Automated weighing & bagging equipment onions and potatoes

LinkExchange SearchMe WhatWeDo AboutUs Sitemap Next page Fully automated 10 head weigher/filler

Fully automated double headed weigher/filler, capable to bag bags as small as 5 kg per units to as big as 25 kg per unit with an capacity...

Weighing and bagging from 5 kg to 25 kg bags.

Model: 2EW-2000-TP plus a Bagging Machine JN-ZK1

Weighing and packing line with a DOUBLE lectronic weigher and a JN-ZK1 bagging machine.

This weighing and packing installation for onions, potatoes, carrots and other similar produce consists out of:

- in-feed elevator,

- double electronic weigher EW-2000_TP

- machine for single bags JN-ZK1

This installation is capable to bag bags of 5 kg to 25 kg.

The reason why these kind of installations are not suitable to weigh and bag bags smaller than 5 kg, with relative big products, like onions, potatoes or root beets, is explained here: weighing principles.

As, can be seen in the picture, the product from, for instance, a grader and passes over a roller inspection table into the hopper of the in-feed elevator, which brings the product to the two 2-belt weighers and from there the product is bagged by the bagging machine called ''Bagmaster''.

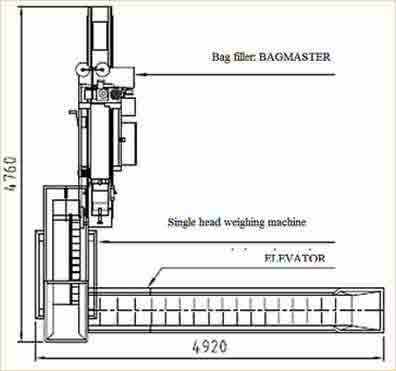

LAY-OUT of a weighing and packing line with a double lectronic weigher and a JN-ZK1 bagging machine.

Capacities:

The bigger the bags the higher the capacity.

- Mash bags of 25 kg: 750 bags per hour or 18.750 kg per hour.

- Mash bags of 10 kg: 1.200 bags per hour or 12.000 kg per hour.

- Mash bags of 5 kg: 1,800 bags per hour or 9,000 kg per hour.

The lay-out of a possible configuration of the installation.

The elevator, weighing and bagging equipment can be aligned in any way imaginable. But this lay-out gives a good impression of the space required for this kind of installation.

Dimensions 4,760 m by 5,310 m.

IMPORTANT: Other packing materials are also possible. It is perfectly okay to place box packing installation or a paper or plastic bag filler at the outlet of the weighing machine.

from 9.000 kg to 18.750 kg per hour depending the size of the bags used.

To mechanise your post harvest processes:

contact us:

Telephone:

+1 239 3002374

or use our (preferable)

our contact form

Address: Farm San Isidro, Volcán, Panama.