Onion and potato box storage, forced ventilation through pressure wall

LinkExchange SearchMe WhatWeDo AboutUs Sitemap Next page Components for automated (computerised) onion and potato storage

Box storage using a pressure wall to facilitate homogeneous ventilation is used as an alternative to bulk storage when:

Storage of onions and potatoes in boxes with forced ventilation, using a pressure wall.

Storing onions or potatoes in boxes has the advantage that the produce is not crushed by being stacked up to 4 metres high. In addition, produce in boxes is compartmentalised, and so in the event of contamination or disease, the problem will not spread throughout the facility, but will be confined to that one box.

Box storage makes it necessary to invest in boxes, but the handling and logistics are very simple. The only specialised equipment you need is a forklift truck. Have a look how bulk storage and box storage facilities are filled and emptied here..

Box storage, with forced ventilation through the produce, is ideal for delicate products, such as short-day onions.

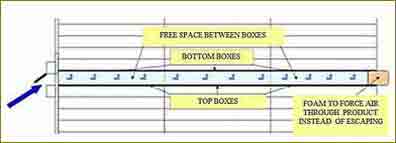

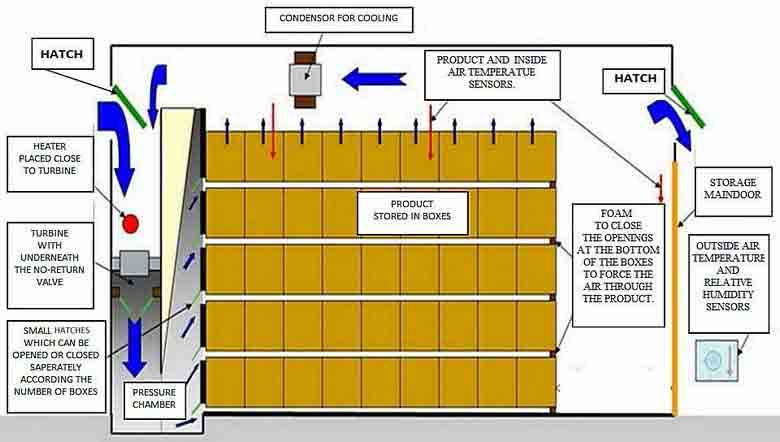

The picture shows a pressure wall. Every ventilation slot can be closed from behind. The pressurised air exits through the slots, and is forced via the pallet-like bottom of the boxes through the produce in the boxes.

Behind the pressure wall is the pressure chamber. To the right-hand side, the ventilation slots can be seen. The function of the pressure chambers is to equalise the pressure so that the same amount of air flows through every slot.

The boxes with onions or potatoes are placed against the pressure wall and the corresponding slots are opened from behind the wall. This picture shows also how flexible this system is.

This picture is taken just above the turbines, which are placed above the pressure chamber. Please note the protection grids, which make it possible to walk over pressure chamber to inspect the hatches.

How does a storage system with a pressure wall and boxes function?

The air is blown in through the small entrance hatches in the pressure wall (see diagram on the left), and flows through the pallet-like bottom of the pressure boxes. The underside of these boxes are hermetically sealed, so the only way out for the pressurised air is through the produce, before leaving through slits at the top of the short sides of each box. For more details on these boxes go to: storage boxes.

At the end of the row, the last pallet is sealed with a piece of foam during operation.

To see more details regarding the major components of a storage system, like: sensors, Multiserver (the brain of the system), boxes to be used etc., please go to: Components of a computerised storage facility.

Requirements for proper operation.

If the produce is suitable for storage, this system works.

The advantages of the system:

- Full control of the climate inside the warehouse

- Possible infections stay confined to one box

- Suitable for potatoes and onions

- Also suitable for delicate onions

- This system allows storage of almost all kinds of fruits

- Flexible system in terms of capacity

- Logistics very simple, only requires a forklift truck

The disadvantages of the system:

- It requires an investment in boxes, but no investment whatsoever in the specialised equipment used for filling and emptying bulk facilities.

Box stored onions, ventilated through a pressure wall.

1) The produce to be stored is not fit for bulk storage for instance produce that is not firm enough to endure the pressure incurred by bulk storage.

In a bulk storage facility, in order to be economically viable, the produce is piled up to 3 to 4 metres high, and certain varieties of onions or potatoes cannot sustain the pressure.

2) The storage facility is a collection centre, where various growers (owners) in the region store their produce. In this case, box storage is the most logical option, because every box or bin can be marked with the name of the owner, which is impossible when the produce is piled in bulk, as there is no way to differentiate between each owner.

3) Another advantage of box storage are the logistics of removing the produce from storage, especially when packaging or processing is carried out in batches. In this case, only a forklift truck and a bin or box tipper is needed.

To mechanise your post harvest processes:

contact us:

Telephone:

+1 239 3002374

or use our (preferable)

our contact form

Address: Farm San Isidro, Volcán, Panama.