Storage box fillers, for onions and potatoes

LinkExchange SearchMe WhatWeDo AboutUs Sitemap Next page Controlled emptying of storage boxes: potatoes and onions.

When a grower uses a box storage system, such as a suction-ventilated or pressure-ventilated system, they need a machine to fill those boxes.

Storage box fillers

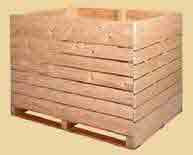

Wooden storage boxes

Box for pressure system. Sealed sides.

Box for suction system. Grooved sides.

There are increasingly more storage facilities where the harvest is stored in wooden boxes, whether they have a pressure wall system or suction wall system. These boxes need to be filled when the harvested produce arrives in tipper trucks or trucks with discharge conveyors. To carry out this task, box fillers have been created:

Box fillers have two key features:

- They fill the boxes in such a way that the onions or potatoes never fall from higher than 25 cm. The machine uses certain sensors to detect the height of the pile which is forming inside the box, and raises the fall point as the box fills up. The mouths of the most sophisticated fillers move horizontally as well as vertically, so that the surface of the pile remains more or less flat, and doesn't need to be levelled out in order to fully fill the box. This is especially important if the storage facility has a suction ventilation system.

- All fillers accommodate two boxes, so that whilst one is being filled, the full one is taken away by a goods lift to the storage facility, then replaced with an empty box. This ensures a continuous flow of produce.

A box filler for onions, potatoes, beetroot or any other produce that is box stored.

Fillers can work in parallel, for example if you want to fill boxes after the produce has been through a grading machine.

One of the most frequent situations where box fillers are used is when the produce comes from the harvest in trucks with a discharge conveyor.

Here you can see how the mouth of the filler keeps the pile of the produce level.

Here are two videos which demonstrate two different box filling systems:

The first system loads the produce into the box using a belt which is guided by sensors, without dropping it and avoiding damage.

The second system breaks the fall of the produce with a pneumatic mechanism, which is also guided by sensors.

Continual box filling for storing onions or potatoes, placing the produce into the box without dropping it.

Continual box filling for storing onions or potatoes, using a fall breaker system to avoid damaging the produce.

These box fillers take the harvested produce and continually load it into boxes without damaging it.

There are two systems:

1. A box filler which loads the produce with a moving belt, guided by sensors, which prevents the produce from falling further than 20 cm.

2. Box filler with a fall breaker, also guided by sensors, which prevents the produce from falling further than 20 cm.

To mechanise your post harvest processes:

contact us:

Telephone:

+1 239 3002374

or use our (preferable)

our contact form

Address: Farm San Isidro, Volcán, Panama.